When some cement products are produced in batches, usua […]

When some cement products are produced in batches, usually manufacturers who produce prefabricated parts will purchase relevant cement molds to produce them in batches, which can greatly increase the output power. However, after pouring into the mold, how to release the cement mold? This time involves more relevant professional knowledge.

Before we know how to demold a cement mold, we must first understand the material or shape of the relevant cement mold for targeted demolding treatment. Here, Lichen Technology mainly introduces the following types of cement molds for specific demolding treatment.

1. Polypropylene and ABS engineering plastic cement molds must be coated with a certain thickness of mold release agent on the inner wall of the plastic mold before casting precast. The mold release agent can generally be engine oil, washing liquid or some other organic solvents. The shape of the preform is coordinated with the related demoulding mechanical equipment to demold, which is the most convenient, and the overall quality of the cement preform after demolding is better, and it is not easy to form defective products such as missing corners and external cracks. Relevant supporting machinery and equipment, such as ordinary cement flat stones, cover plates, etc., cement molds and prefabricated parts are all flat-bottom structure, it is very simple to use the vibration table to adjust the sensational frequency. Or maybe some prefabricated demolding of cement railings can be demolded using a centrifuge. The principle is similar to that of a vibrating table, except that the centrifuge can better ensure the quality of the prefabricated cement in the shape of a cylinder.

2. Cement molds made of steel materials are generally larger in size, so when producing cement steel molds, the mold will be produced with a detachable lock design, and can be altered in the cement steel molds before prefabrication. Some release agent, and then directly remove the lock, screws, nuts and other fixed accessories can be perfect release.

3. Silicone cement mold, the mold of this kind of material is the most troublesome to demold, and the size is generally small. The more common cement silicone molds with prefabricated small flower pots can usually be directly pulled by hand, but if there is no control If the material bubbles of the silicone mold are good, then a relatively small number of small bubbles may also appear on the surface of the cement product, so the practice is a cement mold material that is more difficult to handle and has a low number of repeated applications.

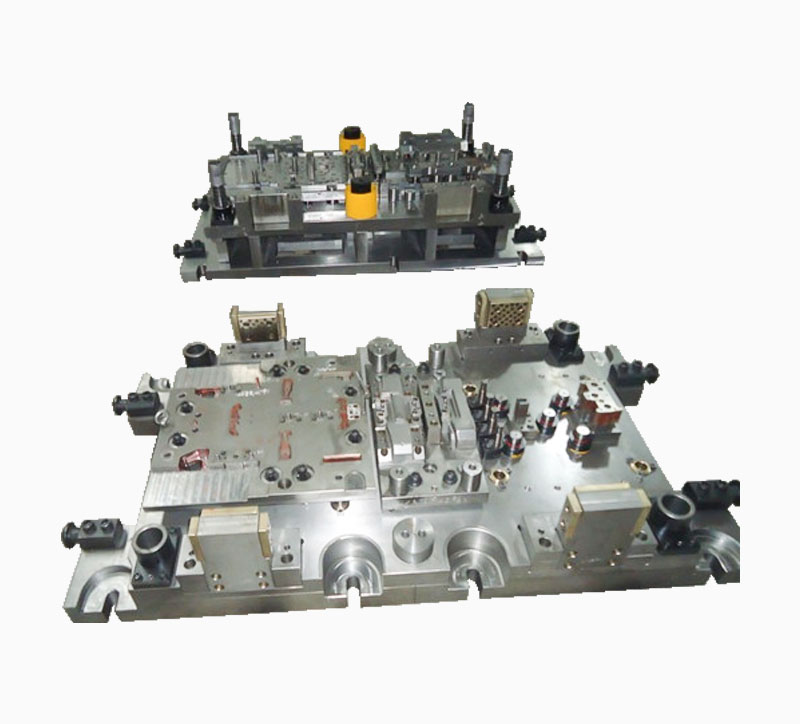

Plastic mould

Generally speaking, how to demold the cement mold is not a topic worthy of too much in-depth discussion. The key is to see whether the quality of the cement prefabricated parts passes after demoulding, whether there are no bubbles in the prefabrication process, or maybe there are No missing corners, drawing cracks, etc.

Please Leave Your Email Or Phone Number,So We Can Contact You As Soon As Possible

Contact us

Taizhou Booling Mould Co., Ltd. is a famous China Plastic Moulds Manufacturers and Extrusion Blow Moulding factory,we produces and deals with various injection mould,extrustion blow moulds and plastic mould machinery,etc.

Languages

Languages