"Mold" is the general term for "fan" that produces parts or semi-finished products.

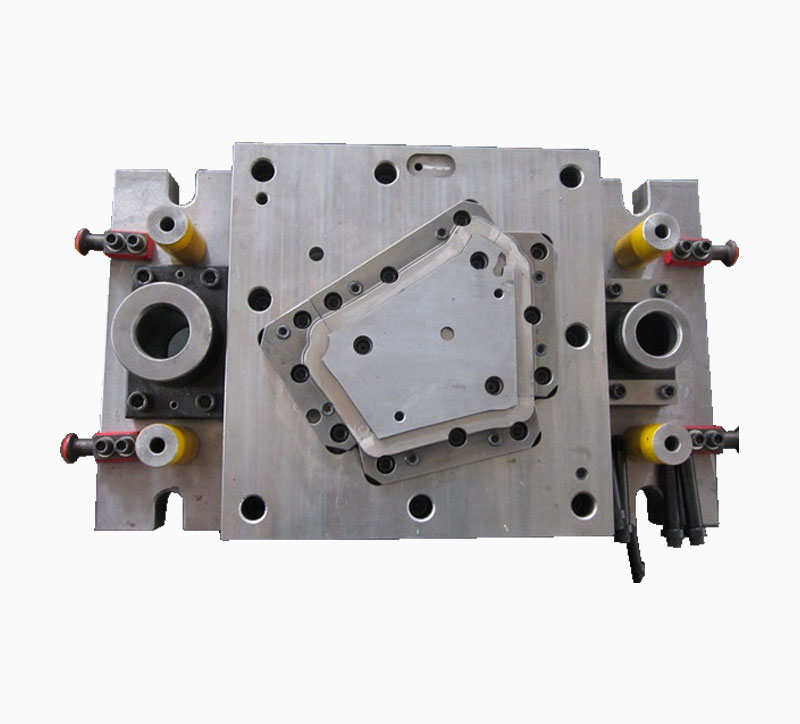

Molds that produce hardware parts (parts) are commonly known as "hardware molds";

The molds that produce plastic products are commonly known as "plastic molds".

In view of the different properties of plastic products and metal products in production and use, plastic molds cannot be used for metal processing.

In the modern processing industry, in batches or even small batches, in order to ensure product quality and output power, there are often processes using molds in the process composition.

Among the common industrial occupations, the occupations that use molds are: casting, casting, stamping, heat treatment (called pressure tools in heat treatment occupations), plastic forming, machining (machined occupations are called masters), powder metallurgy, etc.

During the molding of plastic products belongs to the plastic processing profession;

The production of hardware products can be divided into the occupations listed above.

The purpose of the use of plastic molds and metal molds is to produce products. Therefore, the structural and functional characteristics of each of them are mainly determined by the products produced.

The design of plastic molds is often based on the characteristics of low melting point of plastics. It is equipped with heating (local heating), cooling (local cooling), mold cavity pressure, rapid pressure relief, data leakage alarm and other systems than common hardware molds.

Therefore, clever ideas and complicated processing are often the characteristics of plastic molds.