After the development in recent years, my country's pla […]

After the development in recent years, my country's plastic mold industry has shown the following new development trends in the development of plastic molds, structural adjustments, and corporate management:

Among the four elements of mold quality, delivery cycle, price, and service, more and more users put the delivery cycle in the first place.

Vigorously enhance the ability of automatic development. Mold companies can’t wait for a contract to plan plastic molds based on user requirements. At present, the {HotTag} "you give me a concept, I will give you a product" one-stop service model of Qingdao Haier Mould Company and other enterprises and the automatic development methods of enterprises such as Taicang Qiujing Mould Company have been increasingly used. Accepted by the company.

With the advancement of the planning and processing level of mold companies, mold making is changing from relying primarily on the skills of fitters to relying primarily on skills. This trend has not only made the standardization of molds continuously improved, but also made molds more and more accurate, shorter and shorter production cycles, and lower and lower share of fitters, which eventually promoted the progress of the entire mold industry level, but also strengthened Industrial production of plastic molds started.

Mold companies and their mold production are rapidly developing in the direction of informationization. In the information society, as a high-level modern mold company, the use of CAD/CAM is far from enough. At present, many companies have adopted CAE, PDM, CAPP, RE, CIMS, ERP and other skills and many other advanced production skills and virtual network skills.

In short, my country's plastic molds have a brilliant prospect. Only those plastic mold companies that can grasp opportunities, open up the market, and constantly discover new growth points and companies that can produce high-skilled injection moulds can have a place in the fiercely competitive market.

Please Leave Your Email Or Phone Number,So We Can Contact You As Soon As Possible

Contact us

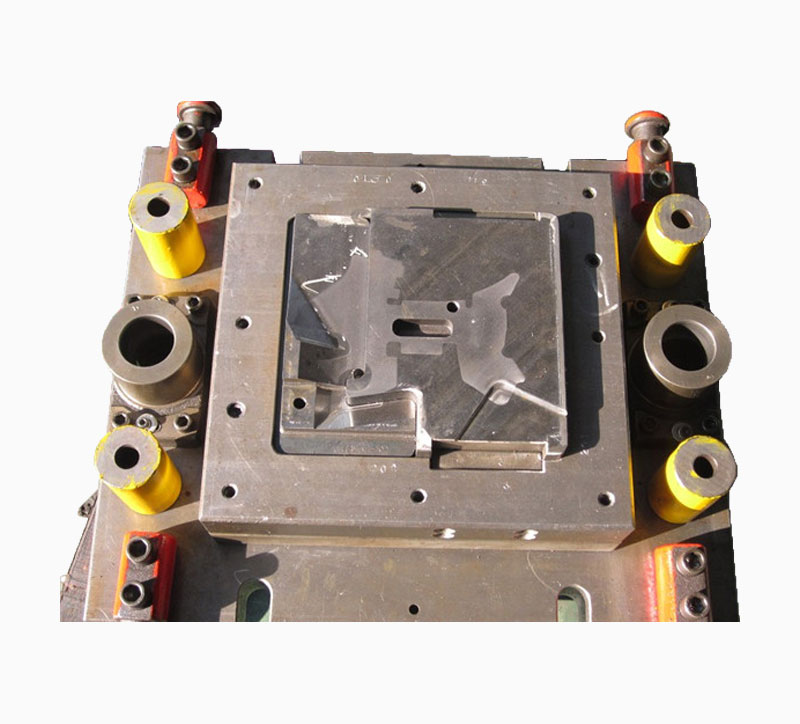

Taizhou Booling Mould Co., Ltd. is a famous China Plastic Moulds Manufacturers and Extrusion Blow Moulding factory,we produces and deals with various injection mould,extrustion blow moulds and plastic mould machinery,etc.

Languages

Languages