1. Processing aspects: (1) Excessive processing pressur […]

1. Processing aspects:

(1) Excessive processing pressure, too fast speed, more filling, too long injection and pressure holding time will cause excessive internal stress and cracking.

(2) Adjust the speed and pressure of mold opening to prevent mold release and cracking caused by rapid forced drawing.

(3) Properly increase the mold temperature to make the part easy to demould, and appropriately lower the material temperature to prevent decomposition.

(4) Prevent cracking due to weld marks and degradation of plastics, resulting in lower mechanical strength.

(5) Appropriate use of mold release agents, and pay attention to frequently removing substances such as aerosol attached to the mold surface.

(6) The residual stress of the workpiece can be treated by annealing and heat treatment immediately after forming to eliminate the internal stress and reduce the generation of cracks.

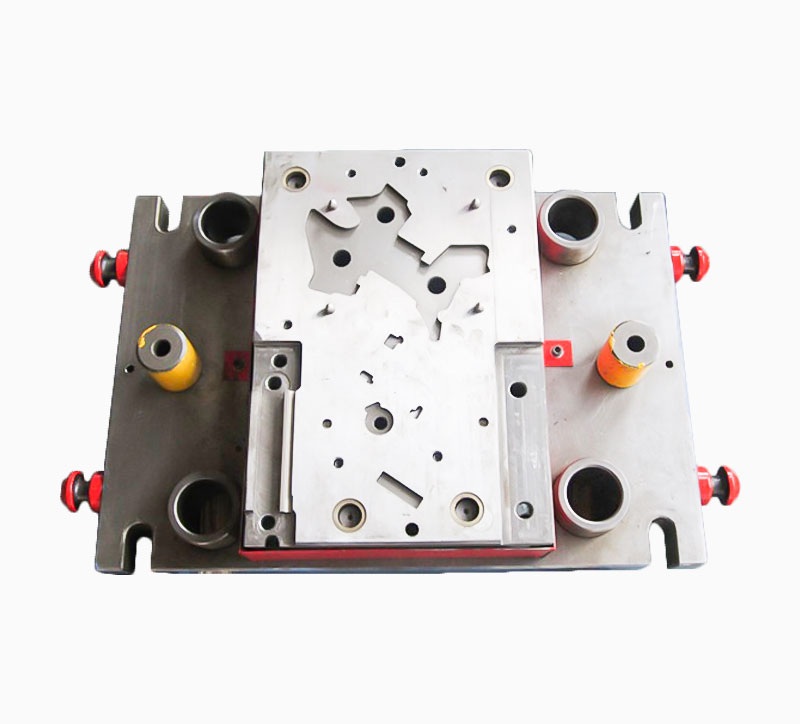

2. Mold aspect:

(1) The ejection should be balanced, such as the number of ejector pins, the cross-sectional area should be sufficient, the demolding slope should be sufficient, and the cavity surface should be smooth enough, so as to prevent the residual stress concentration and cracking caused by the external force.

(2) The structure of the part should not be too thin, and the transition part should use arc transition as much as possible to avoid stress concentration caused by sharp corners and chamfers.

(3) Minimize the use of metal inserts to prevent the internal stress from increasing due to the difference in shrinkage between the insert and the workpiece.

(4) Appropriate demoulding air inlets should be provided for deep-bottomed parts to prevent the formation of vacuum negative pressure.

(5) The main runner is sufficient to allow the gate material to be demolded when it is cured in the future, so that it is easy to demold.

(6) The sprue bushing and the nozzle should be prevented from being dragged by the chilled material to make the parts stick to the fixed mold.

3. Material aspect:

(1) The content of recycled materials is too high, causing the strength of the parts to be too low.

(2) Excessive humidity will cause some plastics to react chemically with water vapor, reduce the strength and cause ejection cracking.

(3) The material itself is not suitable for the processing environment or the quality is not good, and it will cause cracking if it is polluted.

Different injection molds have different requirements.To sum up, the performance requirements of plastic molds for mold steel are mainly reflected in: hardness, polishability, etching performance, welding performance, wear resistance, toughness, dimensional stability, corrosion resistance, etc.

Toolox material can be used in plastic molds with long life and high wear resistance requirements, replacing plastic hard molds produced by 2344, 136, 2083 and other types of materials. Especially high-gloss plastic molds with rapid cold and hot requirements, such as: LCD TV Frame molds for external frames, notebook computers, various displays, automotive interior parts molds, etc.

Toolox is used in plastic molds, the main advantages:

1) High polishing performance, due to the small grain size and low impurity content, Toolox material has very good mirror performance and requires less polishing time. It is easier to polish.

2) Hardness and wear resistance: Toolox series materials are pre-hardened materials, among which Toolox44 material is the hardest pre-hardened die steel in the world. And the processing performance is still very good.

3) Welding performance: Due to the special composition design of the Toolox series of materials, the welding performance is very excellent, and laser welding can achieve very good results.

4) Toughness: Compared with other materials of the same type, Toolox material has better toughness than corresponding materials. The effect of resisting rapid cold and rapid heat is extremely stable. It is especially suitable for high-demand plastic molds using rapid cold and rapid heating technology, which can solve the problem of mold cracking .

5) Etching performance: Due to the fine grain size and low impurity content, the etching performance is very excellent, and the drawing effect is very good.

6) Dimensional stability: Since Toolox series materials are pre-hardened materials and the internal stress is very small, there is almost no internal stress during the mold processing process. It is especially suitable for plastic molds with high dimensional stability requirements, and is especially suitable for replacing non- Pre-hardened plastic molds that require heat treatment.

7) Corrosion resistance: Toolox material has general corrosion resistance. If the mold has corrosion resistance requirements, special surface nitriding-oxidation treatment is required. The corrosion resistance effect is very good, but if the surface treatment process is not used, the corrosion resistance performance is excellent. In 2344, NAK80 and other materials.

4. Machine side:

The plasticizing capacity of the injection molding machine should be appropriate. If it is too small, it will become brittle due to insufficient plasticization. If it is too large, it will degrade.

Please Leave Your Email Or Phone Number,So We Can Contact You As Soon As Possible

Contact us

Taizhou Booling Mould Co., Ltd. is a famous China Plastic Moulds Manufacturers and Extrusion Blow Moulding factory,we produces and deals with various injection mould,extrustion blow moulds and plastic mould machinery,etc.

Languages

Languages