1. Mold processing process regulations First, it is nec […]

1. Mold processing process regulations

First, it is necessary to do a good job of guiding production. When processing products, it is necessary to plan and schedule the production in advance, and train the operating skills of all personnel, and conduct quality inspections and cost calculations on the workpieces. These must be implemented in accordance with the manufacturing process regulations.

The second is to make preparations for production. When the workshop is going to produce new parts, it is necessary to formulate the mechanical processing procedures of the parts and prepare for production according to the manufacturing procedures.

Third, in the case of a new plant, it is necessary to determine the type and quantity of machine tools to be equipped according to the process regulations, as well as the placement of the workshop, and to allocate the type of work and technical level according to the actual situation of the workshop.

2. Mold processing process

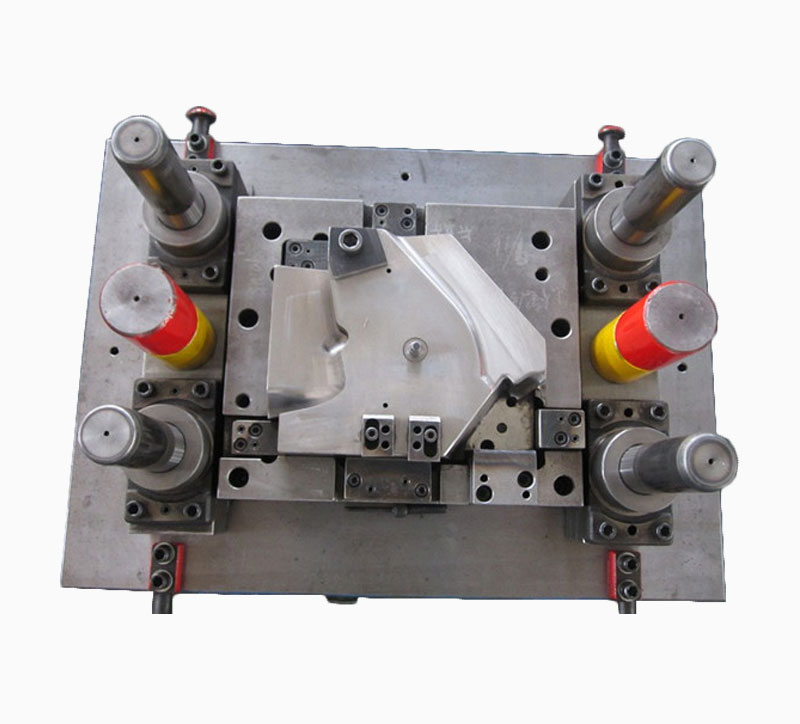

In general, the process of mold processing is drawing review-material preparation-processing-mold base processing-core processing-electrode processing-mold parts processing-inspection-assembly-flying mold-trial mold-production. Under normal circumstances, the customer will either provide a template, or will provide a 3D drawing or 2D drawing. If the customer provides a template, the mold manufacturer will draw the 3D drawing based on the template, and the customer directly sends the 3 drawing. The mold manufacturer will conduct a review. After the review is completed, a consensus is reached with the customer. The next step is to order the mold blank and the inner mold steel material, followed by 3D parting and drawing out. The completion of the mold usually takes 15-20 days. about. In mold making, it is necessary to track the progress of the mold and keep a record. In short, mold processing is an art, and there are many processes involved.

Three, the important role of mold engineers

Mold processing is inseparable from mold engineers. Mold engineers implement customized mold plans for the entire project, design branch products and draw mold parts and assembly drawings. In addition, design and compile mold processing technology to solve problems in production in time Machining process problems, at the same time, will develop new products, new processes, design new molds, and sort out and classify drawings and technical data.

The entire process of mold processing is time-consuming and requires related process regulations to standardize the implementation. At the same time, it also requires strict process flow to complete the production of molds. The production of a piece of mold requires a mold engineer. Important roles play a role.

Please Leave Your Email Or Phone Number,So We Can Contact You As Soon As Possible

Contact us

Taizhou Booling Mould Co., Ltd. is a famous China Plastic Moulds Manufacturers and Extrusion Blow Moulding factory,we produces and deals with various injection mould,extrustion blow moulds and plastic mould machinery,etc.

Languages

Languages