Mold heat treatment is an important means to improve the hardness performance of steel. It is generally carried out after the mold is roughened, and the heat treatment is returned for finishing. However, there are risks during the processing. Improper handling will cause cracks in the steel. Scrap, then what are the reasons for the abnormal plastic mold steel material:

1. The mold material has serious segregation of network carbides.

2. There is mechanical processing or cold plastic stress in the mold.

3. Caused by improper heat treatment of the mold (heating or cooling too fast, improper selection of quenching cooling medium, too low cooling temperature, too long cooling time, etc.).

4. The complex shape of the mold, uneven thickness, sharp corners and thin threaded holes, etc. make the thermal stress and tissue stress remain too large.

5. The heating temperature of the plastic mold is too high during the quenching process to cause overheating or overburning.

6. After the mold is quenched, the tempering is not timely or the tempering holding time is insufficient.

7. When the mold is reworked and quenched, it is heated and quenched again without intermediate annealing.

8. Improper grinding process for mold heat treatment.

9. During EDM machining after the heat treatment of the mold, there are high tensile stresses and microcracks in the hardened layer.

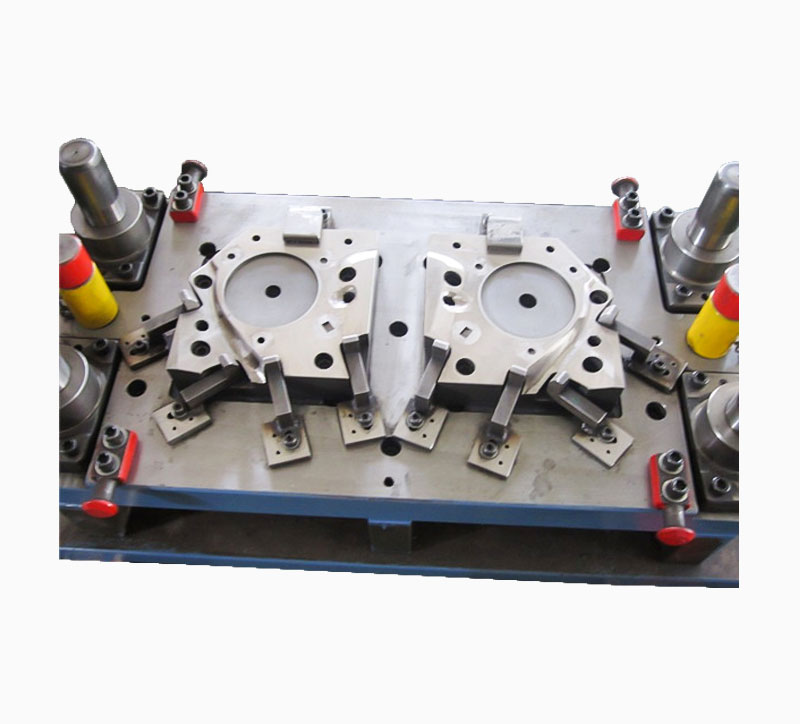

Related Product: Precision Melt Blown Nonwovens Mould